STIRRUP SURFACE

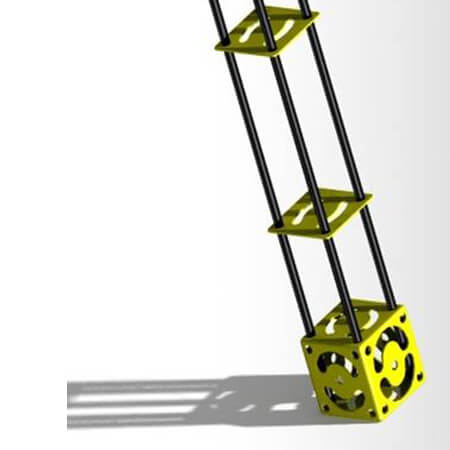

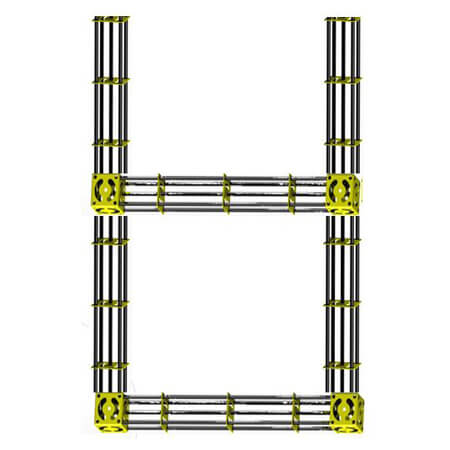

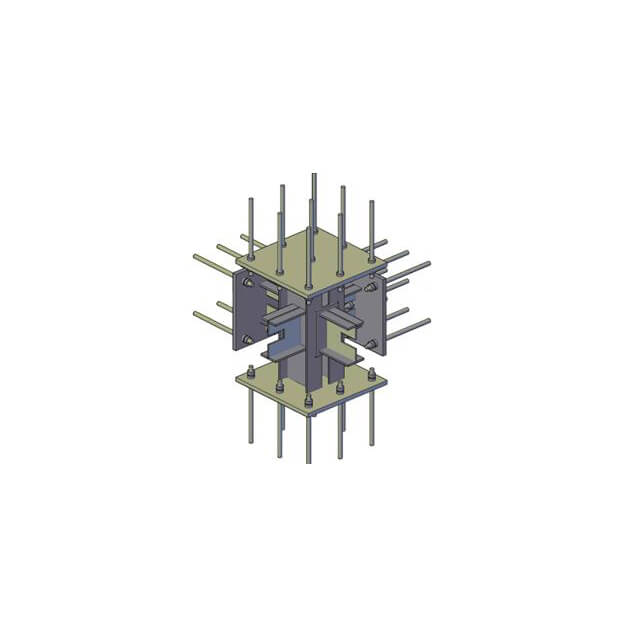

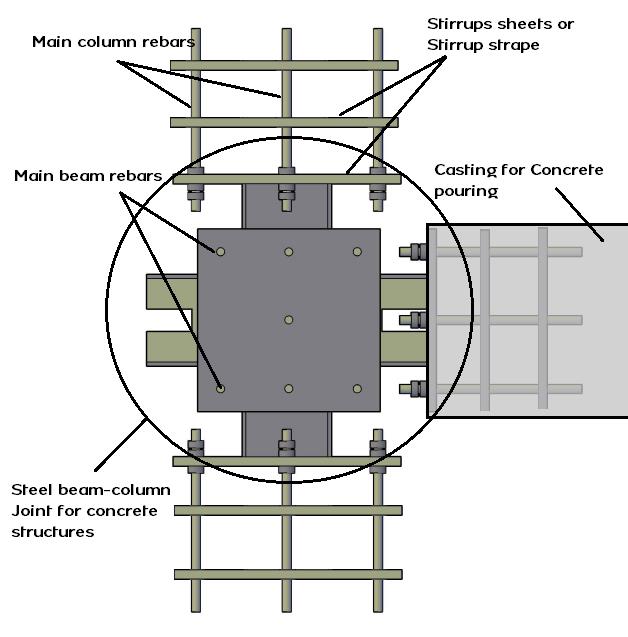

In this product, instead of using stirrup for bars of concrete structures for buildings and bridges, structural sheets with flexible thickness are used. In fact, instead of every 3-4 stirrups, a structural sheet is used and a rebar can be added to the center to reduce the cross section of the column and achieve the required strength. In Stirrup Surface technique, the types of rebars required in the concrete frame, such as braces, stirrups, and pins, are completely eliminated.

THE PROBLEMS WE ARE FOCUSING ARE:

To build concrete structures in high-rise buildings and bridges, a lot of time is always wasted on bending rebars and bracing by workers. In addition, stirrups are very heavy and cost a lot of iron, and bending the rebar to produce a stirrup reduces the strength of the rebar at the bending part. This problem in high rise buildings and bridges constructions is very important to save time, money, and enhance buildings and bridges structure.

OUR SOLUTION

Our solution is that instead of bending rebars to create stirrups in building and bridge structure, Stirrup Surface technology is invented and produced a structural sheet. This technology uses thread at the joints, which does not require welding. The dimension of Stirrup Surface product and its holes are based on engineering calculations which may be unique in each project. The production time for each Stirrup Surface product is 1 second for per sheet.

In a standard level, Sheets thickness is 1cm, and are installed each 75 cm on structure. In places close to the structural supports where the shear force increases, a sheet is placed every 20 cm to prevent this force. These sheets are emptied through press process in the workshop according to the customer’s order, the exact location and number and diameter of the rebars, as well as the location of the concrete.