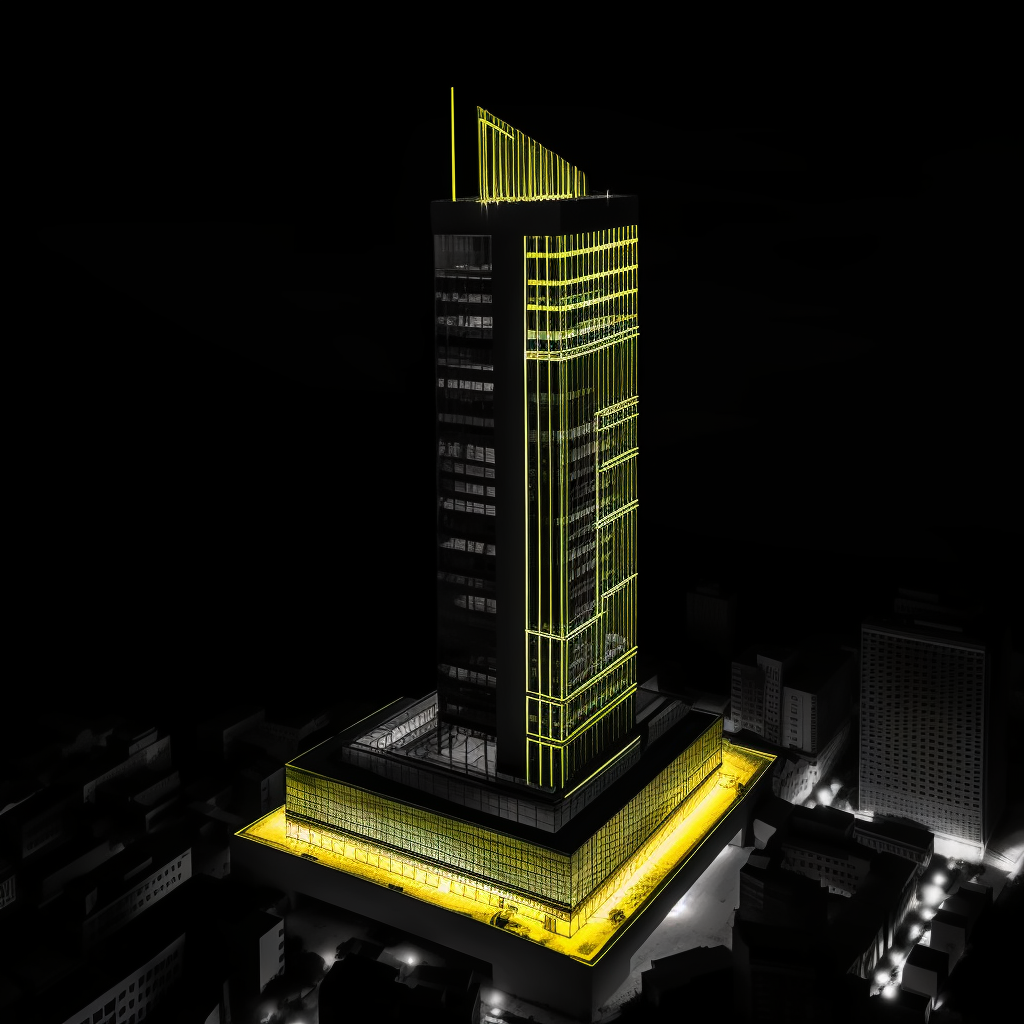

THE ADVANTAGES OF STIRRUP SURFACE

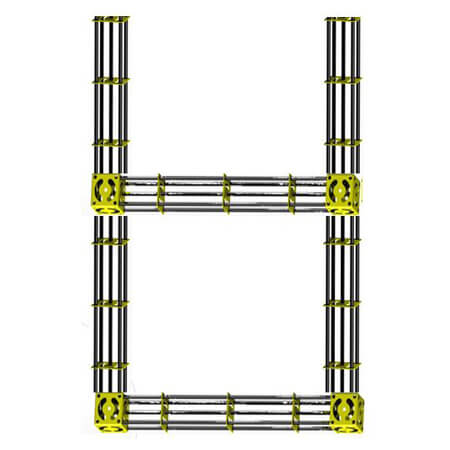

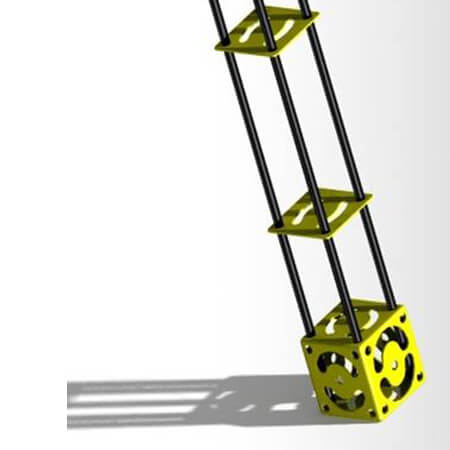

Our innovative Stirrup Surface product replaces traditional stirrups in concrete structures with flexible structural sheets. Instead of the usual 3–4 stirrups, a single structural sheet is employed with rebar placed at the center, reducing the column’s cross-section while maintaining the required strength. Moreover, the Stirrup Surface technique eliminates the need for various types of rebar, such as braces, stirrups, and pins, simplifying the construction process and minimizing material waste.

- Collaborate with fellow architects.

- Showcase your projects.

- Experience the world of architecture.

SAVE TIME AND BUDGET

- Half the cost compared to the embossing method

- Speed in concreting operations

MORE ACCURACY IN INSTALLATION

- The diameter of the columns is reduced

- Does not require rigid alignment in concreting

- Higher strength and resistance than current stirrup

+ Advantages

THE PROBLEMS WE ARE FOCUSING ARE:

Building concrete structures in high-rise buildings and bridges is often hampered by the time-consuming and labor-intensive process of workers bending rebars and bracing. Additionally, stirrups are not only heavy but also costly in terms of materials and can reduce the strength of the rebar when bent.

WE CONNECT

SMARTLY

Prefabricated pre-assembled structure elements

- Collaborate with fellow architects.

- Showcase your projects.

- Experience the world of architecture.

Prefabricated pre-assembled structure elements

- A world of thought-provoking articles.

- Case studies that celebrate architecture.

- Exclusive access to design insights.

Our team

Our company started operating in 2020, and since then, it has been conducting research and implementation activities on construction improvement solutions. With the help of our expert team, we have been able to implement strong solutions related to the construction of building structures with better performance and lower operating costs, and we continue to do our best in this direction.

WE CONNECT SMARTLY