What Is Stirrup?

A stirrup is a closed loop of rebars in a reinforced concrete component that keeps the main reinforcement (RFT) bars together. Stirrups may be of various types depending on the design and shape of the structural members. They are often used in reinforced concrete beams and columns to help them resist bending and shear forces.

Stirrups are typically made from round or deformed steel bars and are placed perpendicular to the main longitudinal reinforcement bars within the concrete structure. They serve as lateral ties, holding the vertical bars together and providing stability to the concrete structure.

The spacing and size of the stirrups are determined by the engineer based on the structural requirements of the project. The stirrup’s shape and dimensions must be precise to ensure that it fits snugly around the longitudinal bars and does not interfere with the placement of other reinforcing elements.

Stirrups play a crucial role in ensuring the stability and durability of concrete structures. They help prevent cracks and failure due to bending and shear forces, which can occur as a result of loads applied to the building, such as wind or earthquakes.

Stirrup applications in Construction?

Stirrups are an essential component of reinforced concrete structures and are widely used in construction for their ability to resist shear, torsion, and bending forces. Stirrups are small steel bars that are bent into a U-shape or other shapes and placed diagonally across the longitudinal reinforcement bars in concrete beams, columns, and slabs.

- One of the primary applications of stirrups is in beams, where they help to prevent diagonal cracking by resisting shear forces. When a beam is subjected to a load, it tends to bend and create tension in the bottom portion of the beam while compression occurs in the top portion. Stirrups are used to transfer the shear forces between the two portions, thereby preventing the formation of diagonal cracks.

- In columns, stirrups are used to resist lateral forces, such as earthquakes or wind loads. They are typically placed at regular intervals along the length of the column and help to confine the concrete within the column, increasing its strength and ductility.

- Stirrups are also commonly used in the construction of slabs, where they help to distribute the loads evenly across the entire slab. This helps to reduce stress concentrations and prevent premature failure.

- In summary, stirrups are a critical component in reinforced concrete structures and play an essential role in ensuring their strength and durability. Their applications include resisting shear forces in beams, lateral forces in columns, and distributing loads in slabs.

Types Of Stirrups Used in Construction

Different types of stirrups based on different conditions are described below.

1. Types Of Stirrup Based On Shape:

i) Rectangular Stirrup – This type of stirrup is rectangular and is commonly used in reinforced concrete structures to provide structural strength and stability. Rectangular stirrups are typically placed perpendicular to the main reinforcing bars and are designed to resist shear forces.

ii) Square Stirrup – Square stirrups are similar to rectangular stirrups, but they have a square shape instead. They are also used for providing shear resistance in reinforced concrete structures.

iii) Circular or Round Stirrup – This type of stirrup is circular and is used in reinforced concrete structures to provide structural support and resistance against lateral forces. The circular stirrup is often used in columns and beams.

iv) Triangular Stirrup – As the name suggests, the triangular stirrup has a triangular shape. It is primarily used in reinforced concrete structures to offer better structural stability against diagonal tension forces. This type of stirrup is often used in cantilever structures such as retaining walls.

v) Stirrups on a Spiral – This type of stirrup is typically used in reinforced concrete structures with spiral reinforcement. These stirrups follow the spiral pattern of the reinforcing bars and are used to maintain the spacing between the bars and ensure that they do not buckle under load.

2. Types of Stirrups Based on the Nature of Construction

- Single-legged Stirrups (Open Stirrup):

These are stirrups made from a single straight rod bent into a U-shape with two legs. They are used in constructions where the bars are closely spaced and provide support to vertical bars that aren’t interconnected. Single-legged stirrups are not commonly used in construction because they can be difficult to install and don’t provide much lateral support.

- Two-legged or Double-legged Stirrups (Closed Stirrup):

These are the most commonly used types of stirrups in construction. They consist of two straight rods bent into a U-shape with four legs forming a closed loop. They are used in constructions where the bars are widely spaced and provide more lateral support than single-legged stirrups. Two-legged stirrups require at least four rods to be completed.

- Four-legged Stirrups (Closed Stirrup):

These stirrups consist of four straight rods bent into a rectangular shape with eight legs forming a closed loop. They are used for larger reinforcement requirements and provide greater lateral support than two-legged stirrups. Four-legged stirrups are typically used for beams or other structures where additional reinforcement is required.

- Six-legged Stirrups (Closed Stirrup):

These stirrups consist of six straight rods bent into a hexagonal shape with twelve legs forming a closed loop. They are used for even larger reinforcement requirements than four-legged stirrups. Six-legged stirrups are typically used for columns or other large structural elements that require significant reinforcement. They provide excellent lateral support and help prevent the structure from collapsing under heavy loads.

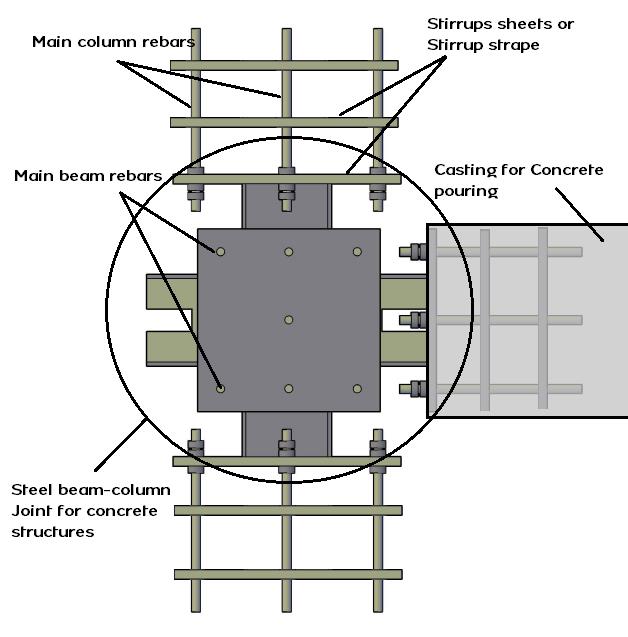

- Stirrup surface

Instead of bending rebars to create stirrups in building and bridge structures, Stirrup Surface technology was invented and produced a structural sheet. This technology uses thread at

the joints, which do not require welding. The dimension of the Stirrup Surface product and its holes are based on engineering calculations which may be unique in each project. The production time for each Stirrup Surface product is 1 second per sheet.

Innovative features

- The dimension holes and surface of this product are based on the base of scientific research to eliminate current stirrups in buildings and bridges

2. Production of rectangular cans with concrete-eating cavities.

3. Removing the rebars needed for the coils such as stirrups, pins, and …

4. Much higher accuracy than the current stirrup method.

5. Production of 3-way reservations for fast closing of waiting rebars.

6. All cuts, bends and arches of the plates are based on calculations.

Based on what we’ve discussed, it seems that the stirrup surface is superior to other types. Other features include:

- Saving time and budget

- Half the cost compared to the embossing method

- The diameter of the columns is reduced

- More accuracy in installation

- High Speed in concreting operations

- Higher strength and resistance than the current stirrup

- Does not require rigid alignment in concreting

Purpose Of Stirrups

Stirrups are an essential component in reinforced concrete construction. They are used to provide lateral and vertical support to the main longitudinal reinforcement bars, also known as rebars, which are placed in a concrete structure to resist tensile forces. Here are ten purposes of stirrups in construction:

1. Preventing shear failure: Stirrups help prevent diagonal cracking due to the shear force acting on the beam.

2. Enhancing the ductility of concrete structures: Stirrups enhance the ductility of concrete structures by confining the concrete in compression, allowing it to deform plastically before failure.

3. Improving the bond between concrete and steel: Stirrups improve the bond between concrete and steel, resulting in a stronger and more durable structure.

4. Reducing spacing between bars: Stirrups allow for a reduction in the spacing between bars, which can lead to a more economical design.

5. Supporting rebar during construction: Stirrups hold the rebar in place during construction, ensuring that the bar remains correctly positioned.

6. Providing structural integrity: Stirrups provide structural integrity by preventing structural members from buckling or collapsing.

7. Distributing loads evenly: Stirrups distribute the loads evenly throughout the structure, reducing the likelihood of localized failures.

8. Resisting earthquake forces: Stirrups increase the resistance of a structure to earthquake forces by improving its ductility and strength.

9. Reducing deflection: Stirrups reduce deflection by increasing the stiffness of structural members.

10. Enhancing durability: Stirrups enhance durability by preventing corrosion of the reinforcing steel, which can weaken the structure over time.

Some Design Consideration

How To Calculate the Length of a Stirrup?

Measuring the length of a stirrup is a really easy process. Here is what you can do:

Consider that you’re measuring the length of a stirrup used in a 0.30m x 0.30m beam; now find the perimeter length of the beam, i.e., 0.30m x 4 sides = 1.20m.

Now you have to consider clear cover (which is 1 inch for all sides, both in vertical and horizontal directions) spacing for concrete.

Deduce 8 inches (an inch is 2.54cm), which is approximately 0.20m from the beam’s perimeter length, which gives us 1.00m.

Lastly, you need to add 2 inches to each end of the stirrup rod while bending to a square shape which gives 1.10m (1.00m + .10m)

How Far Apart Do Stirrups Have to Be?

Spacing between Stirrups in Beam and Column:

According to the standard regulations and guidelines, the maximum width of the beam shall not exceed 300 mm or 12′′ and the minimum shall not be less than 100 mm or 4′′. The usual stirrup spacing is 6′′ to 7′′ (150–180mm) inside the center and 4′′ to 5′′ (100–125mm) just at the column’s end support.

Spacing between Stirrups in the Column:

According to the applicable regulations and guidelines, a maximum spacing of 300 mm or 12 inches shall be allowed per column with minimum widths of 100 mm or 4 inches. Standard stirrup spacing is 6′′ to 7′′ (150–180mm) in the middle and 4′′ to 5′′ (100–125mm) at the end support of the column.

Spacing of Stirrups near the Support End:

Stirrup spacing towards the support end is reduced to a minimum due to the supports’ maximum shear forces. The support end of the rectangular beam and column should have a minimum separation of 6′′ to 7′′ (150–180mm).

Conclusion

If you don’t provide proper specifications of stirrups, spacing in the construction building may collapse, so the designer should preferably specify the spacing of the stirrups along with the structure.

In conclusion, stirrups play a crucial role in reinforcing concrete structures and ensuring their durability and safety. The choice of stirrup type depends on various factors, including the design requirements, the size and shape of the structure, and the construction materials used. Common types of stirrups include rectangular, circular, helical, and spiral stirrups, each with its advantages and disadvantages. Understanding the different types of stirrups and their applications is essential for engineers and construction professionals to ensure that they choose the right stirrup type for their projects and adhere to the necessary safety standards.

Leave a Reply